TVD Hydro Impregnation

Breathable, water-repellent impregnation

TVD Universal Impregnation

Breathable, water- and oil-repellent impregnation

Nanocoatings - ultra-thin, efficient & resistant

Applied as easily as paint!

Our highly efficient liquid thermal insulation is applied like paint. The resulting dried, ultra-thin film is UV-resistant, non-flammable (A2), vapor-barrier, and non-toxic.

The product is sustainable and contains no harmful substances. The thermal conductivity of the coating, Lambda λ, is 0.0010 W/m×K. This means a 1 mm layer of our coating provides thermal insulation equivalent to 60 mm of conventional insulation, e.g., ETICS with Styrofoam WLS 040.

This thermal insulation is functional in a temperature range from -60 °C to +200 °C and can even withstand +260 °C for short periods. The liquid thermal insulation addresses a wide range of challenges in the coating and insulation sector and prevents condensation and corrosion on metallic surfaces.

The manufacturer's warranty is at least 30 years.

The efficiency of our products is based on the following aspects:

Our products do not rely on heat-conducting air but on a vacuum, which results in significantly lower thermal conductivity compared to systems like Styrodur or other air-chamber systems.

The surface of our coating, due to its structure and composition, is many times larger than that of Styrofoam or Styrodur, for example, enabling large-scale reflection of heat radiation/IR radiation. Temperature-resistant and highly efficient materials in the nanoscale allow us to achieve excellent insulation properties in just a few millimeters using natural resources like glass and ceramics.

Our highly efficient liquid thermal insulation is applied like paint. The resulting dried, ultra-thin film is UV-resistant, non-flammable (A2), vapor-permeable, and non-toxic.

The product is sustainable and contains no harmful substances. The thermal conductivity of the coating, Lambda λ, is 0.0010 W/m×K. This means a 1 mm layer of our coating provides thermal insulation equivalent to 60 mm of conventional insulation, e.g., ETICS with Styrofoam WLS 040.

This thermal insulation is functional in a temperature range from -60 °C to +120 °C. The liquid thermal insulation addresses a wide range of challenges in the coating and insulation sector. When applied externally to building envelopes, the coating insulates highly effectively while allowing water vapor and air to pass through due to its breathability.

The manufacturer's warranty is at least 30 years.

The efficiency of our products is based on the following aspects:

Our products do not rely on heat-conducting air but on a vacuum, which results in significantly lower thermal conductivity compared to systems like Styrodur or other air-chamber systems.

The surface of our coating, due to its structure and composition, is many times larger than that of Styrofoam or Styrodur, for example, enabling large-scale reflection of heat radiation/IR radiation.

Temperature-resistant and highly efficient materials in the nanoscale allow us to achieve excellent insulation properties in just a few millimeters using natural resources like glass and ceramics.

Our highly efficient, acrylic-based liquid protective coating can create a strong and durable protective layer with up to 220% elasticity for both indoor and outdoor applications.

Due to its UV resistance, non-flammability, non-toxicity, weather resistance, and vapor-permeable properties, it forms a water barrier that remains breathable and withstands temperatures from -60°C to +80°C.

Our coating is water-based and can be easily applied with a roller, brush, or trowel. It is also hygiene-certified and reduces future hazardous waste issues, as it can be reapplied without removing previous product residues.

The manufacturer's warranty is at least 15 years.

The efficiency of our products is based on the following aspects:

We work with naturally durable elements, ensuring long-lasting and resistant solutions.

The surface of our coating is structured to handle unevenness, cracks, or other substrate changes without issues.

The coating remains impermeable to water while allowing diffusion from the substrate, supporting moisture escape.

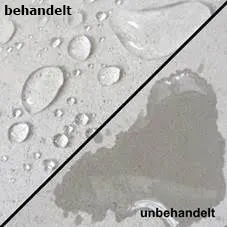

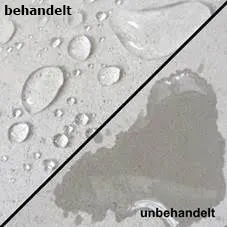

Our water- and oil-repellent impregnations are transparent and specially developed for various porous surfaces. When applied to facades, they do not alter the appearance, natural porosity, or structure of the surface. They enhance thermal insulation properties and extend the lifespan of coatings and structures. Additionally, they prevent the accumulation and penetration of water and organic liquids.

TVD Hydro Impregnation and TVD Universal Impregnation generally protect surfaces from water (plus), oil (pro), and stains such as everyday dirt, coffee, soft drinks, graffiti, and even urine. They facilitate removal through simple washing with water and standard cleaning processes.

The impregnations can be used both indoors and outdoors. Our products are solvent-free, non-toxic, and characterized by high abrasion resistance, UV resistance, and durability with a 10-year manufacturer's warranty.

Breathable, water-repellent impregnation

Breathable, water- and oil-repellent impregnation

The efficiency of our products is based on the following aspects:

We work with natural elements to create long-lasting and resistant solutions.

Our impregnation transforms the surface structure into a nanostructure, preventing water- or oil-based substances from penetrating and allowing them to simply roll off.

The impregnation remains repellent to water and oil while allowing diffusion from the substrate, supporting moisture escape.